ADB success stories

Air Disinfection Biosecurity (ADB - patent pending) technology can be used in many different applications to inactivate disease-causing viruses and bacteria in the air and on surfaces. ADB can also neutralize mold and mildew and control unpleasant odors. Below are just a few examples of some ADB success stories.

Healthcare - Family Practice

Air Disinfection Biosecurity can be used in many healthcare applications, such as doctor's offices, clinics, hospitals, and more. ADB can help protect patients and staff from the spread of potentially dangerous pathogens.

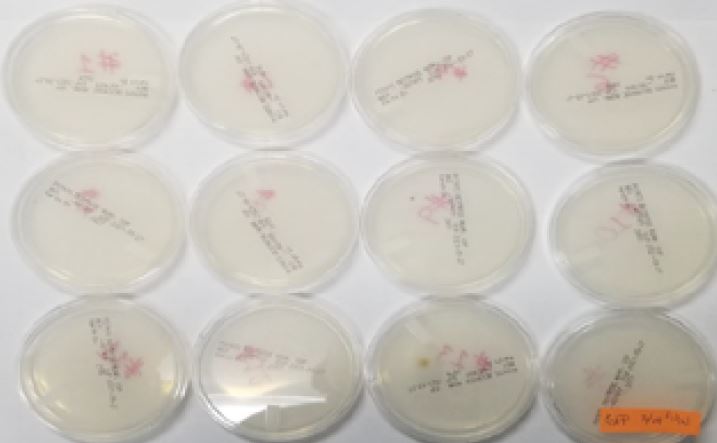

PathogenFocus ADB units were installed at a primary care clinic. In this installation, multiple units were installed in the ductwork throughout high-risk areas. Samples were taken prior to and during ADB treatment. Results are below.

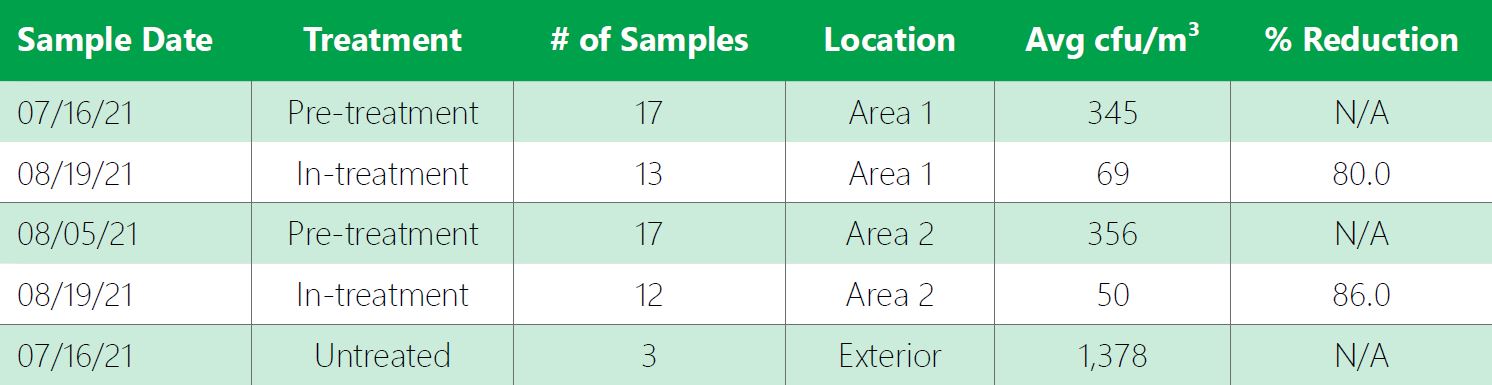

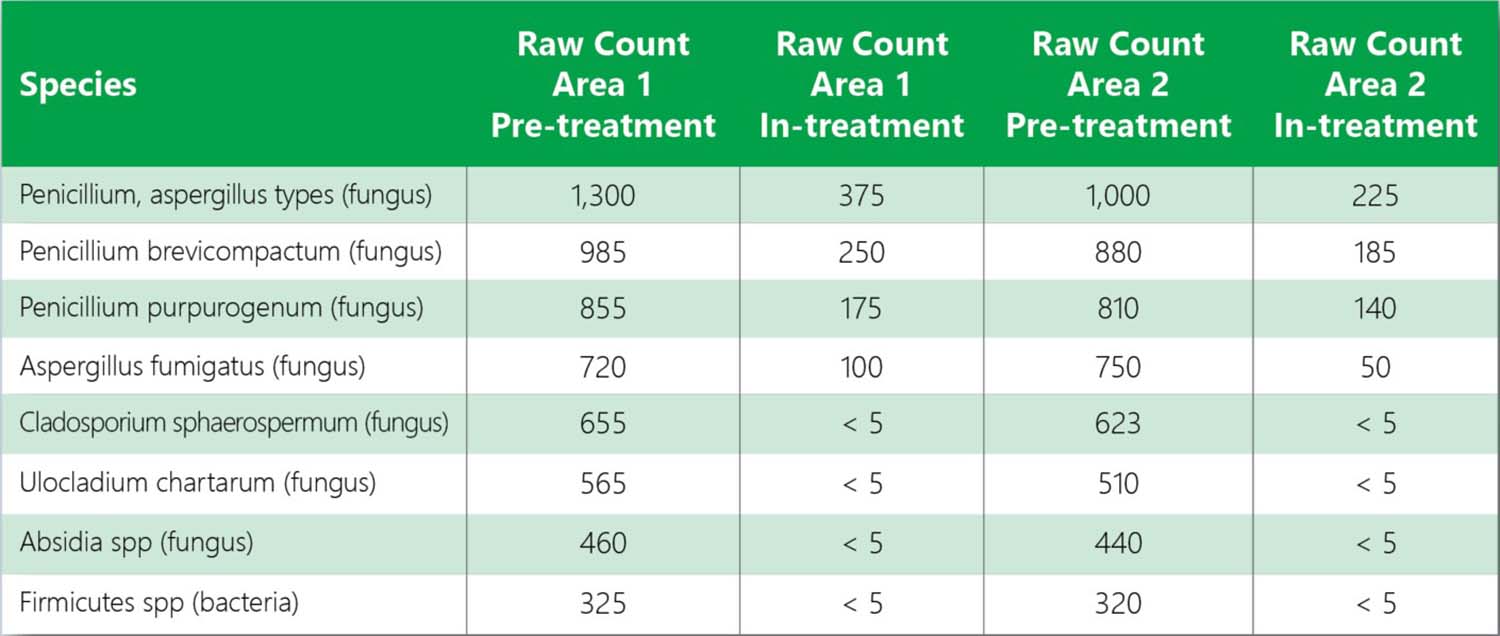

AIR SAMPLES

A series of pre-treatment air samples were taken on July 16, 2021 and August 5, 2021, and in-treatment samples on August 19, 2021. Exterior untreated samples were also taken during those times.

Noted below are airborne organisms found during the pre-treatment and in-treatment sampling, excluding outside samples.

AREA 1

Pre-Treatment

In-Treatment

AREA 2

Pre-Treatment

In-Treatment

The initial bioburden from the pre-treatment samples showed an average of 345 and 356 cfu/m3 for Areas 1 and 2, respectively. At greater than 300 cfu/m3, this is considered not acceptable and needs corrective action.

In-treatment samples showed an 80 percent and 86 percent reduction in airborne organisms for Areas 1 and 2, respectively. At less than 100 cu/m3 this is now considered clean and acceptable.

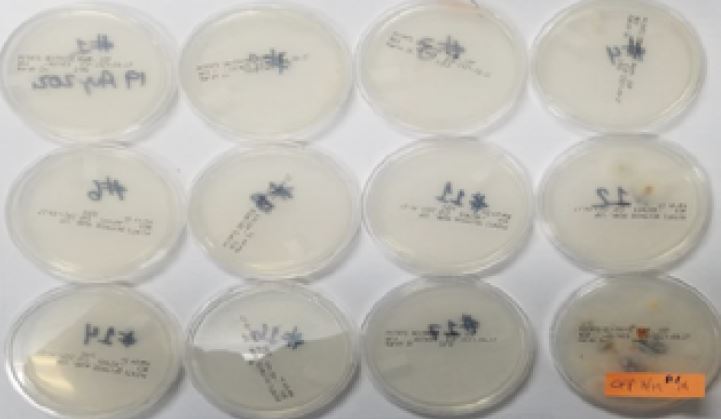

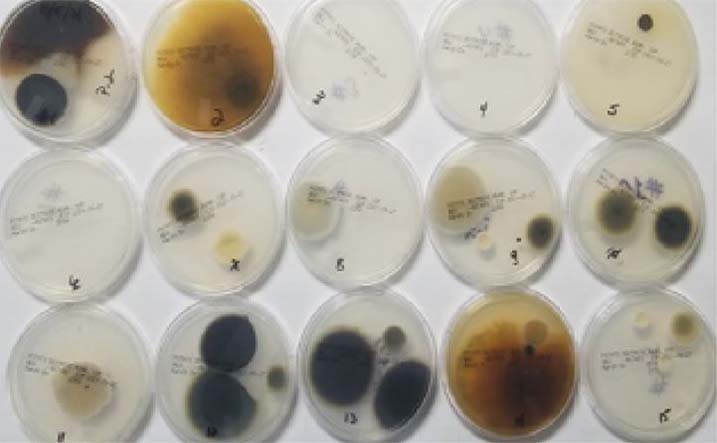

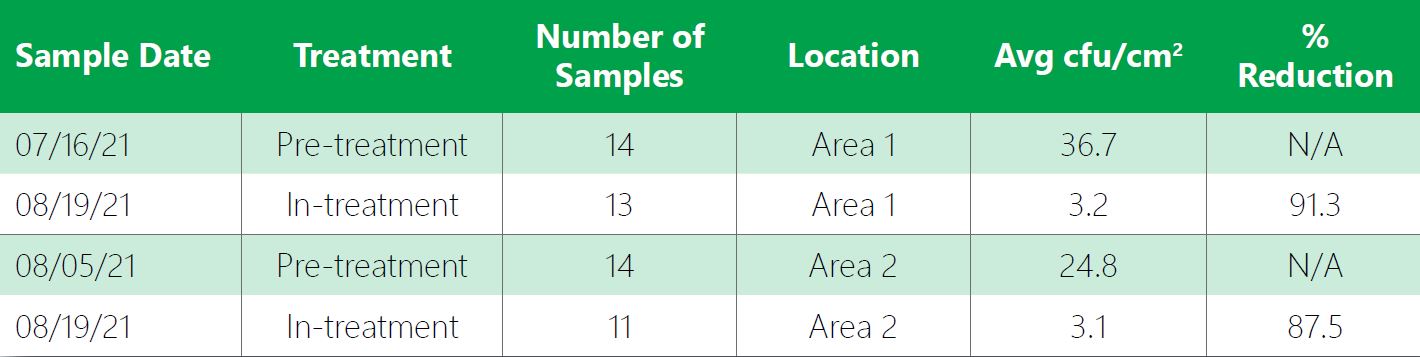

CONTACT SAMPLES

A series of pre-treatment contact swabs were taken on July 16, 2021 and August 5, 2021, and in-treatment contact swabs on August 19, 2021.

Pre-treatment samples showed an average of 36.7 and 24.8 cfu/m2 for Areas 1 and 2, respectively. This is substantially greater than 10 cfu/cm2, which is considered not acceptable and needs corrective action.

The in-treatment swabs, taken on August 19, 2021, showed an average of 3.2 and 3.1 cfu/cm2 for Areas 1 and 2, respectively. That's a 91.3 percent and 87.5 percent reduction in bioburden. At less than 5 cfu/cm2, these areas are considered clean and acceptable. Continued treatment will further reduce these counts.

Food Retail - Bar

ADB can also be used in restaurants and bars to help keep staff and patrons protected from disease-causing bacteria and viruses. ADB can also combat mold and fungus growth, control odors, and extend shelf life of produce. In this case study, samples were taken prior to and during treatment. Results are below.

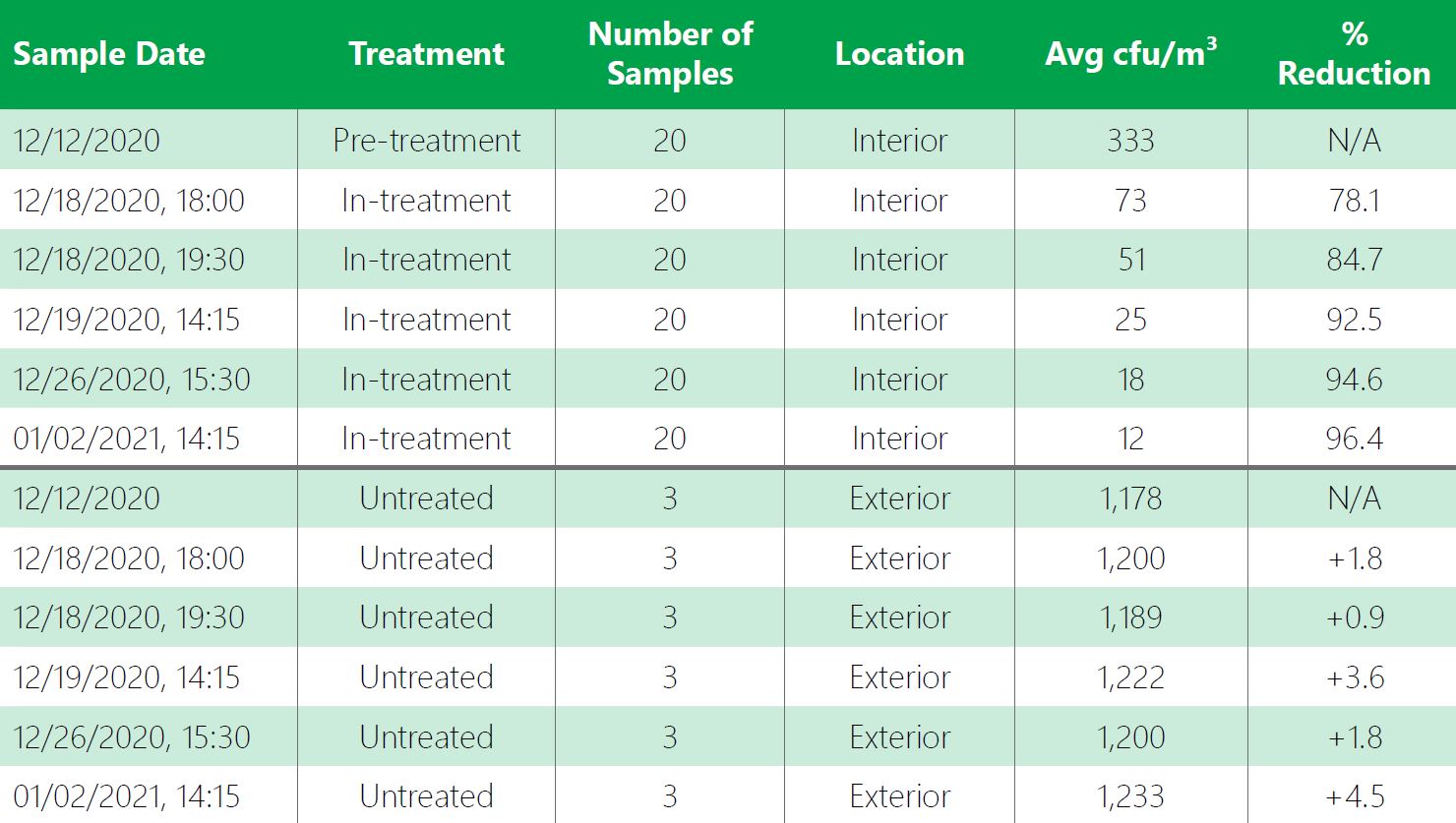

AIR SAMPLES

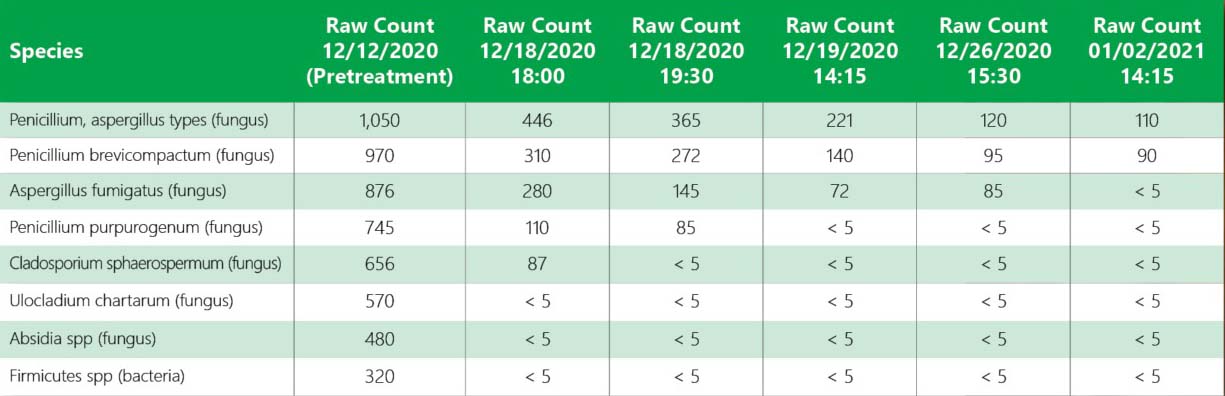

A series of air samples were taken pre-treatment, on December 12, 2020, and in-treatment, on December 18, 19, and 26 in 2020, and again on January 2, 2021. Exterior untreated air samples were also taken during those times. You can see that ADB very quickly made a tremendous improvement, and the area continued to get even cleaner over time.

Noted below are airborne organisms found during the pre-treatment and in-treatment sampling, excluding outside samples.

The initial bioburden from the pre-treatment samples taken on December 12, 2020 showed an average of 333 cfu/m3, which is greater than 300 cfu/m3, and considered not acceptable, needs corrective action.

Sampled areas showed a 96.4 percent reduction in airborne organisms over a 3 week time. The final in-treatment samples taken on January 2, 2021 showed an average of 12 cfu/m3 and is now considered clean and acceptable.

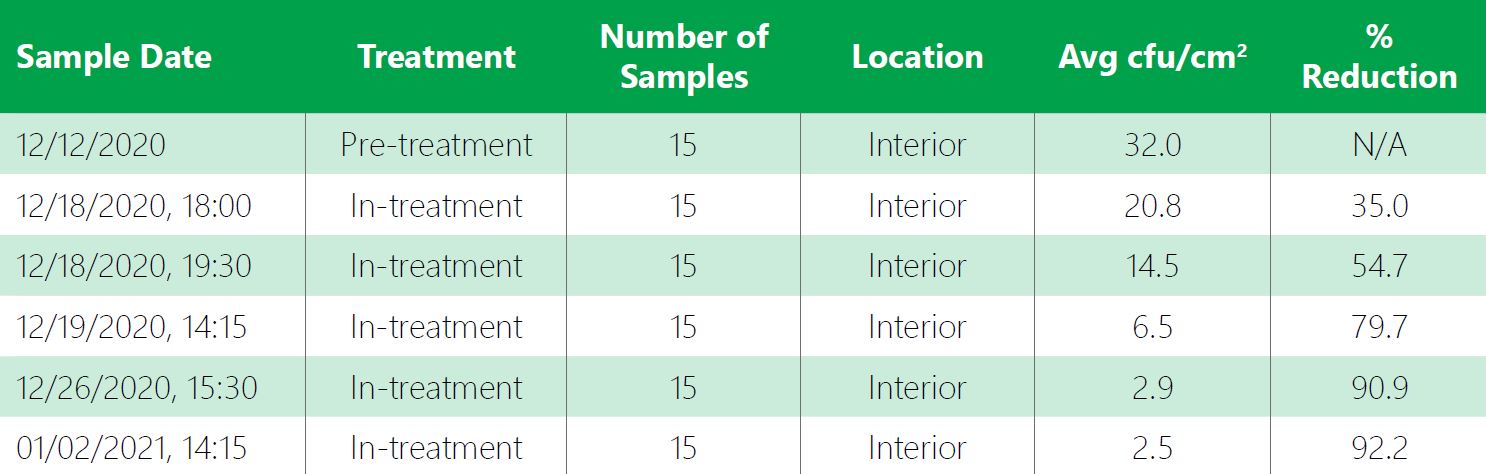

CONTACT SAMPLES

A series of contact swabs were taken pre-treatment, on December 12, 2020, and in-treatment, on December 18, 19, and 26, as well as January 2, 2021.

Pre-treatment results from December 12, 2020 showed an average of 32.0 cfu/cm2 - substantially greater than 10 cfu/cm2, which is considered not acceptable and needs corrective action.

Each set of swabs showed an overall decrease in bioburden over time for the areas examined. The final set of swabs taken January 2, 2021 showed an average of 2.5 cfu/cm2, a 92.2 percent reduction. At less than 5 cfu/cm2, these areas are considered clean and acceptable. Continued treatment will further reduce these counts.

"We selected ADB because the product utilizes a safe, scientifically validated antimicrobial technology that achieves continuous inactivation and neutralization of viruses, bacteria, molds, mildews ... through an advanced air and surface disinfection process. Third-party laboratory studies showed that Air Disinfection Biosecurity technology can destroy viruses in the air within one minute. The ability to neutralize pathogens when one person exhales and another inhales is critical to halting the transmission of COVID as an airborne disease."

- Christopher Vendetti, 10% Solutions

Perishable Food Company

Air Disinfection Biosecurity can be used to treat meat and produce - to neutralize bacteria, mold, and mildew that could cause spoilage. ADB has been proven to extend the shelf life of meat and produce. For the below case study, samples were taken pre-treatment and about 10 months after treatment at a perishable food company.

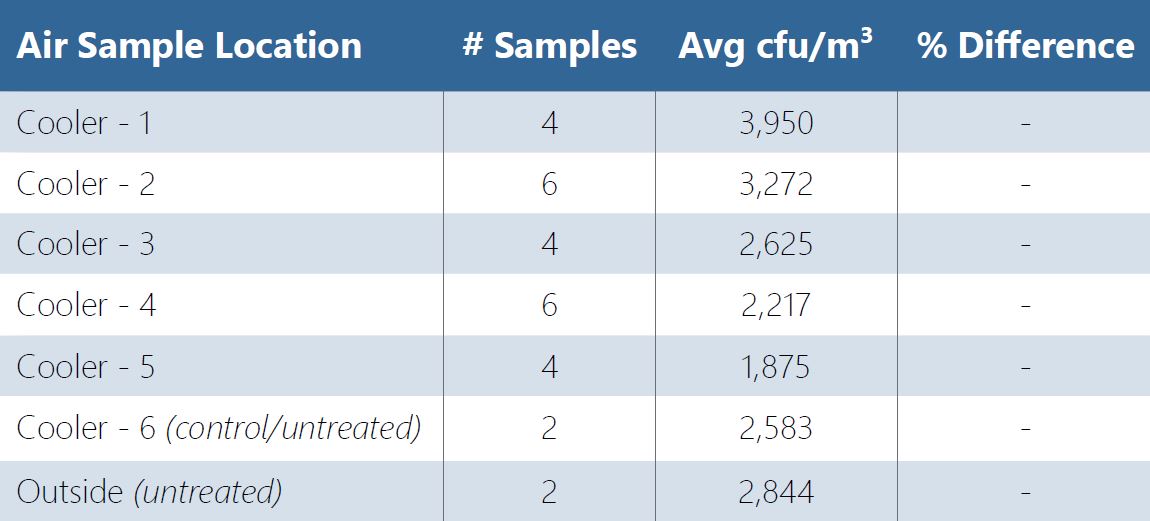

AIR SAMPLES

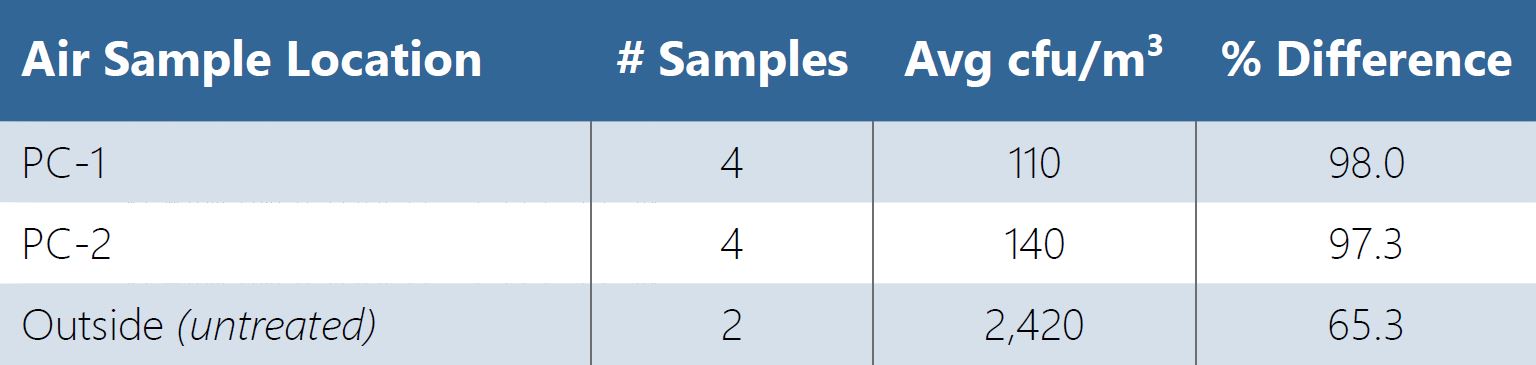

Below is the data gathered from the samples collected prior to the treatment with Air Disinfection Biosecurity.

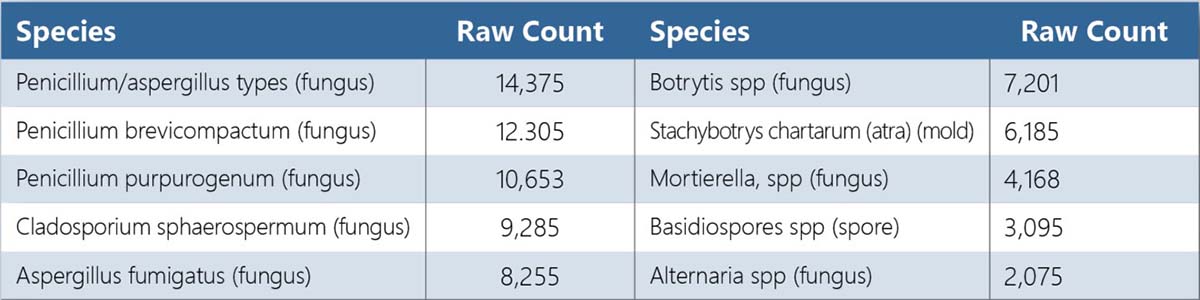

Noted below are the airborne organisms found during the pre-treatment data collection.

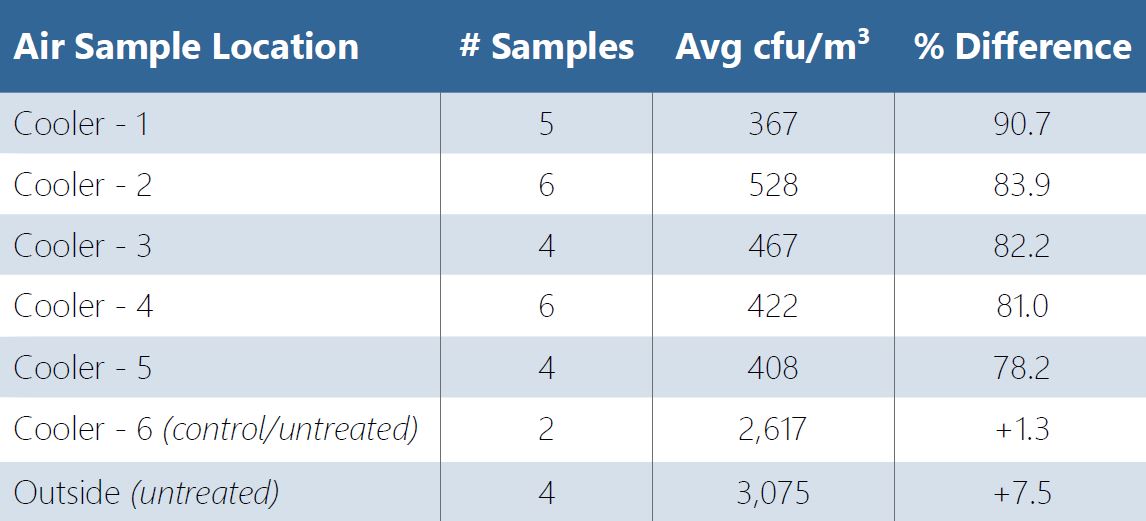

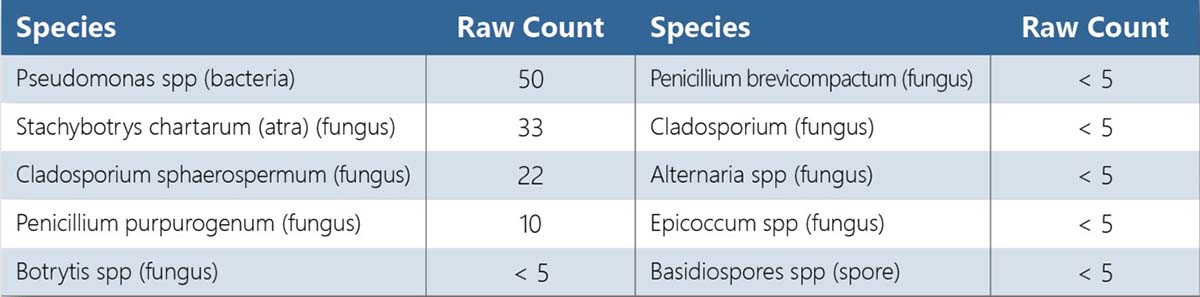

Below is the air sample data collected during treatment. Utilizing ADB significantly decreased the amount of airborne microorganisms.

Noted below are the airborne organisms found during ADB treatment.

Sampled areas showed a 78.2 percent to 90.7 percent reduction in airborne organisms. Ongoing treatment will continue to decrease the bioburden to acceptable levels.

Meat Processing

Food handling areas are extremely vulnerable to cross contamination that results in reduced quality, increased spoilage and the potential for foodborne diseases. Maintaining best practices in meat processing begins in the slaughterhouse and continues through the final packaging - raw or cooked. At every process stage, ADB can be used efficiently and effectively to reduce microorganisms that threaten product quality and shelf life because it is an extremely effective antimicrobial that neutralizes all known pathogens including Listeria, Salmonella, Campylobacter, E. coli, Bacillus and Norovirus.

ADB reinforces standard hygiene and enhances protection in food handling and preparation through the following ways:

- Effective raw meat sanitation and post-lethality disinfection

- Surface sanitation on food-contact and non-food-contact surfaces

- Process equipment such as knives, cutters, saws and gloves

- No impact on organoleptic quality of product

- Extends shelf life

- No hazardous waste disposal

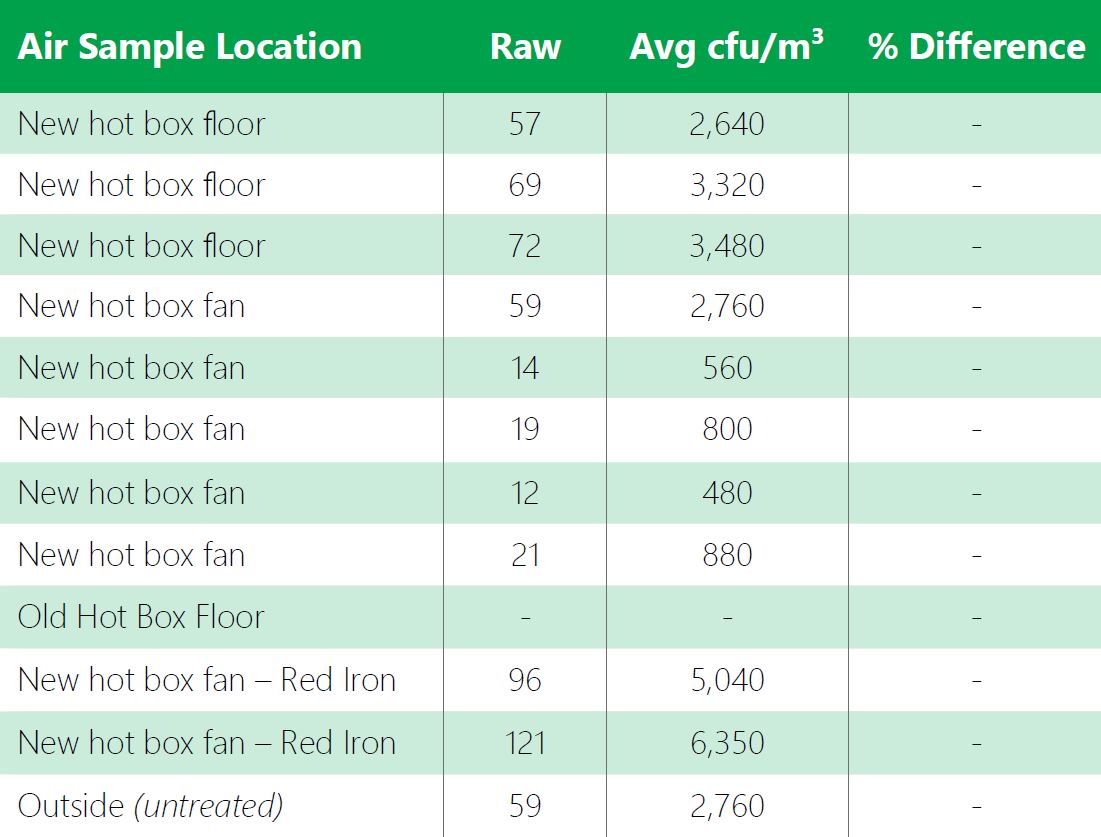

In this case study, pre-treatment air samples were taken in various locations in the facility. Pre-treatment samples from the various locations ranged from 480 to 3,480 cfu/m3, which is considerably greater than 300 cfu/m3 and is considered not acceptable and needs corrective action.

Pre-treatment data is below.

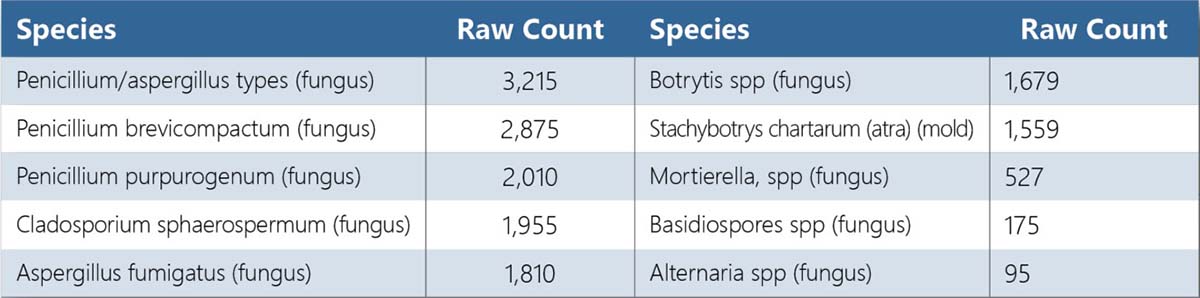

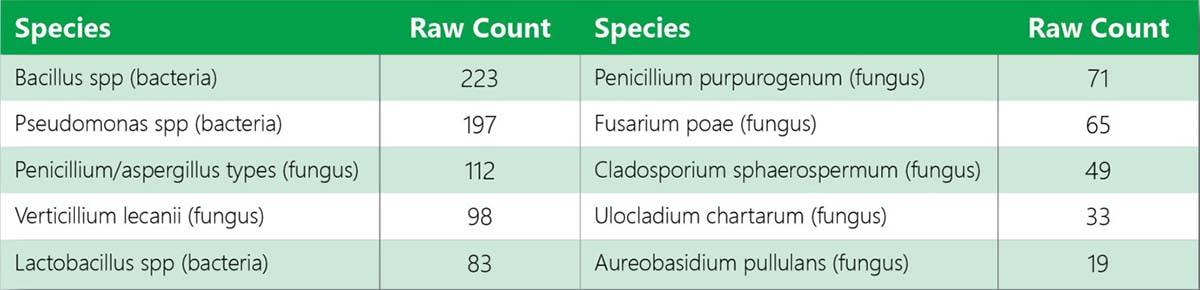

Noted below are the airborne organisms found during the pre-treatment data collection.

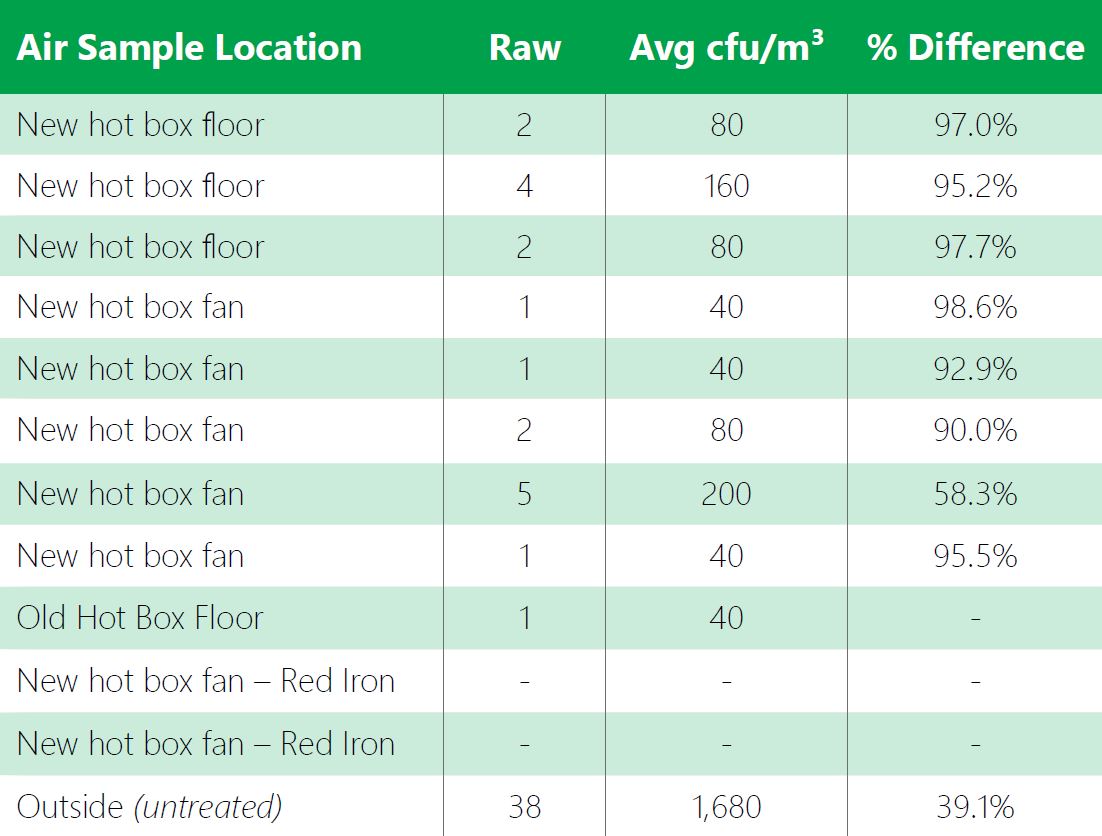

Below is data from the in-treatment airborne samples. Samples from the various locations show a 94.9 percent reduction and range from 40 to 200 cfu/m3.

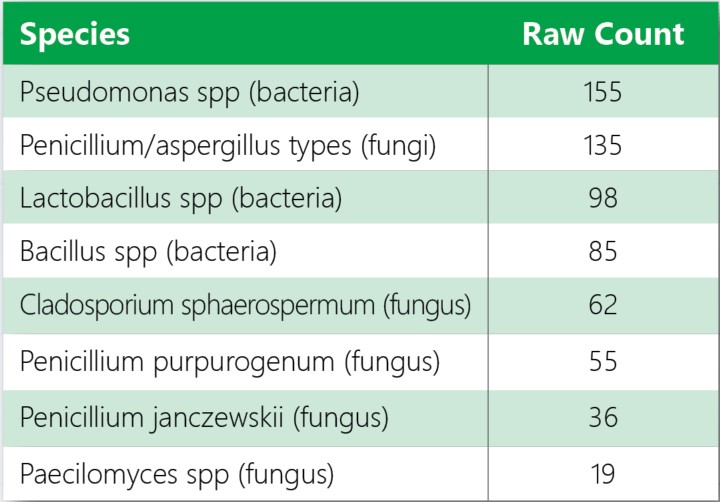

And below are the airborne organisms found during the in-treatment data collection. Utilizing ADB showed a tremendous reduction in these organisms.

Grocery Store

Air Disinfection Biosecurity can treat bacteria, mold and mildew that can cause spoilage in meat and produce. ADB has been proven to extend shelf lives of these products. Because ADB is designed for use in occupied settings, and can minimize airborne and surface disease-causing pathogens quickly and effectively, it is a great solution for grocery stores to help keep customers and employees protected from illness-causing microbes.

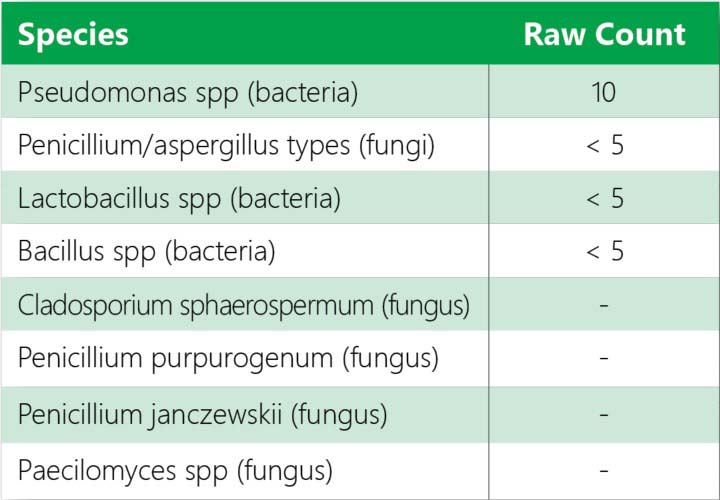

Below is a case study from a food retail establishment. A series of air samples and contact swabs were taken pre-treatment and in-treatment. Below are the types of organisms found during the initial pre-treatment sampling:

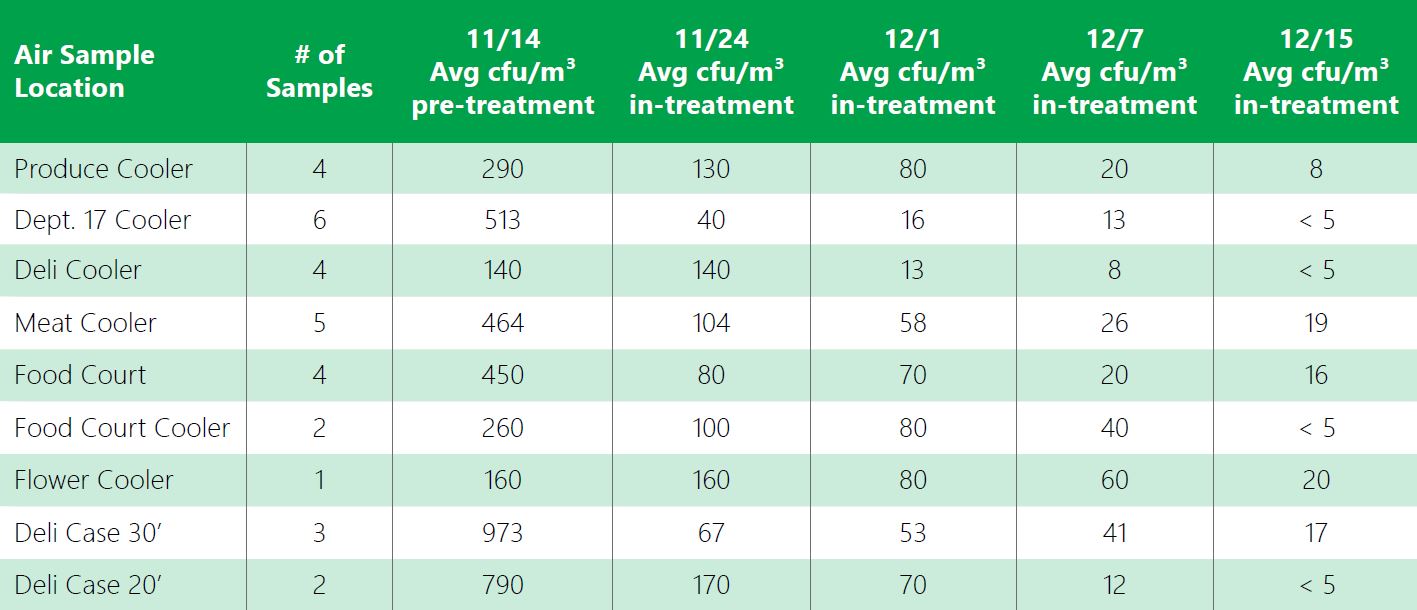

The below chart shows the comparison of the air samples before and in-treatment. As you can see, ADB made a significant difference in the number of microorganisms.

The initial bioburden from the various locations ranged from 80 cfu/m3 to 1,560 cfu/m3, which is considerably greater than 300 cfu/m3 and is considered not acceptable, needs corrective action.

The final in-treatment samples from those same locations ranged from less than 5 cfu/m3 to 40 cfu/m3, and is now considered clean and acceptable.

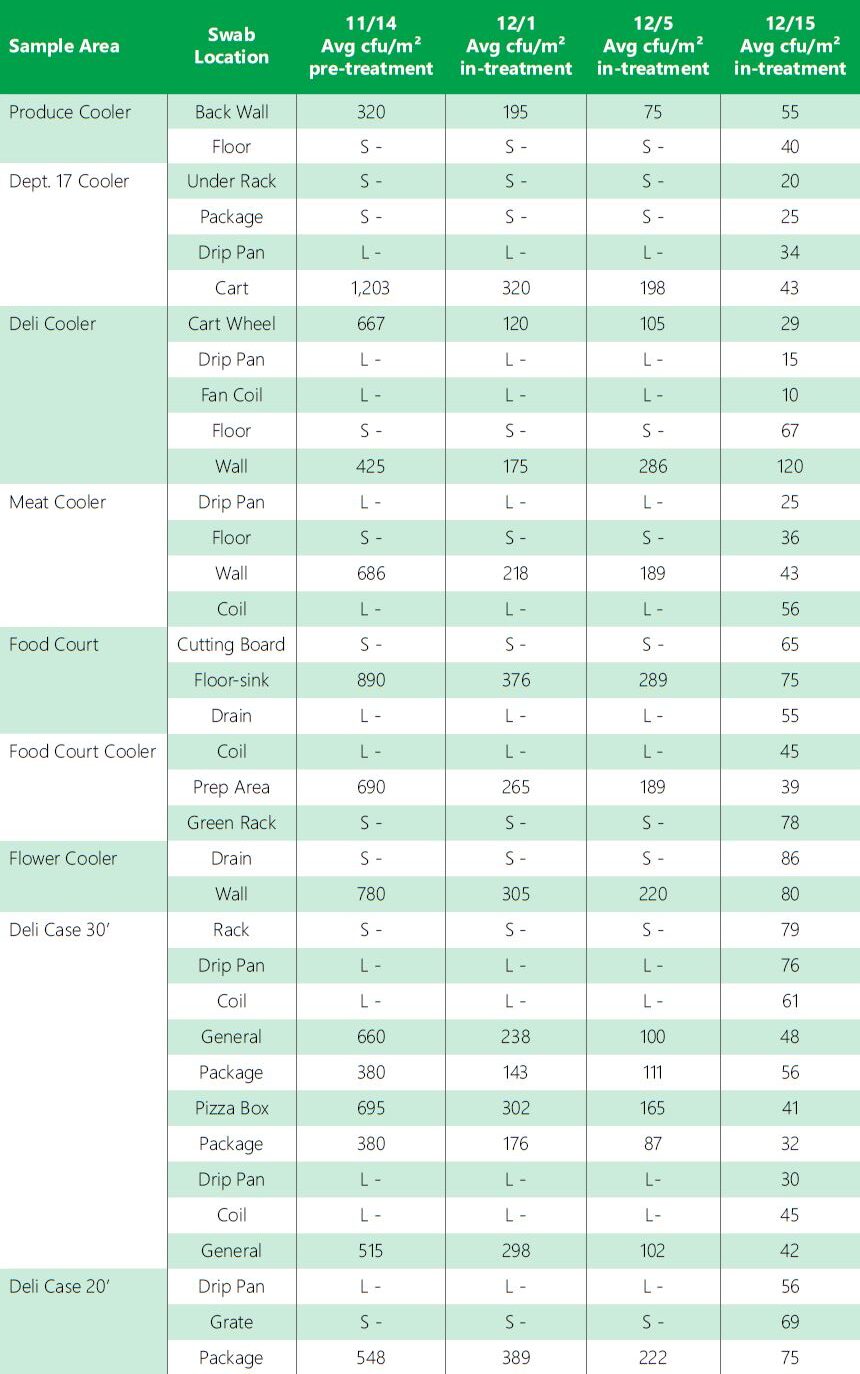

The below chart shows the results from the swab samples gathered from various locations in the store. Note: "L -" means "Listeria negative," and "S -" is "Salmonella negative."

The initial bioburden determined by contact swabs taken from the various areas ranged from 320 to 1,203 cfu/m2.

Each set of swab showed an overall decrease in bioburden over time for the areas examined, with the final set of swabs ranging from 10 to 120 cfu/m2.

Cold Storage

ADB can be used in cold storage and refrigeration to extend the shelf life of produce and meat. ADB can neutralize bacteria, mold and mildew that can cause spoilage. In the below case study, samples were taken prior to and during ADB treatment in a cold storage facility.

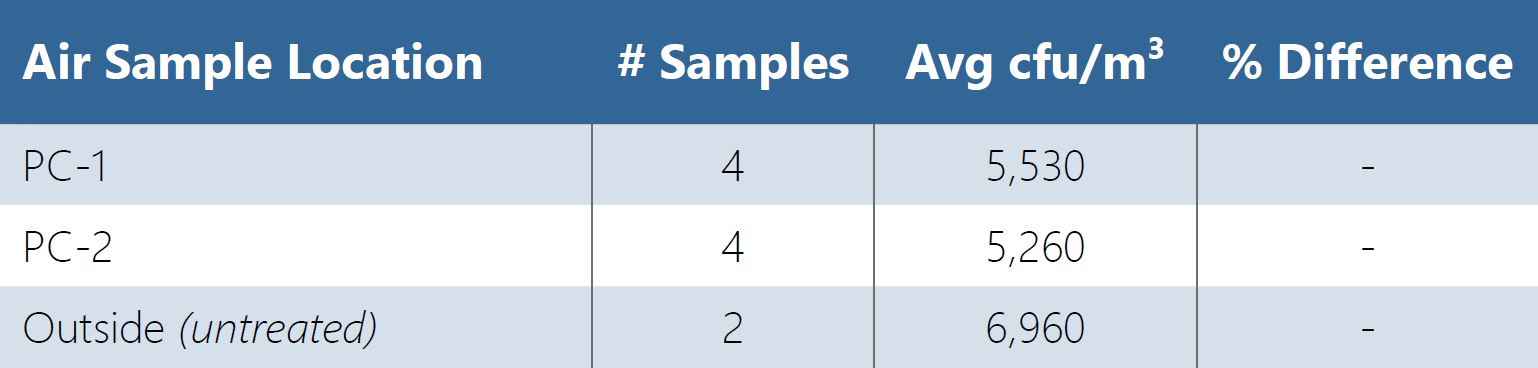

The below chart shows pre-treatment data gathered from air samples in three different locations.

The below chart shows the microorganisms gathered from the pre-treatment air samples.

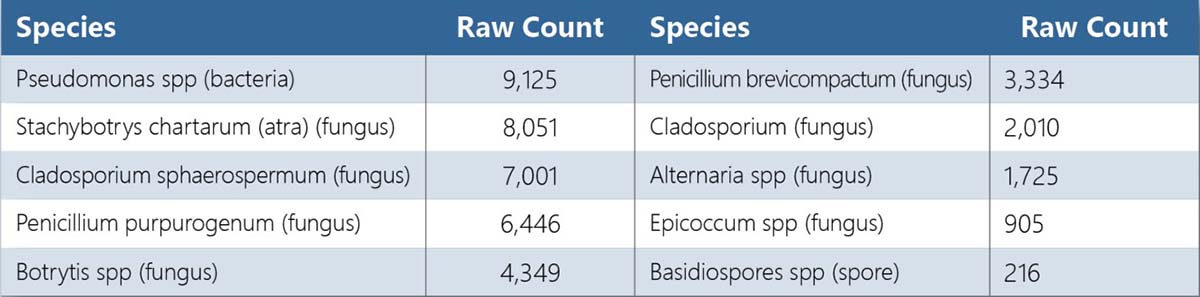

The below chart shows the data gathered from the in-treatment air samples. As you can see, ADB made a tremendous difference.

And below you see the difference in the raw count of microorganisms in-treatment.

Sampled areas showed a 98 and 97.3 percent reduction in airborne organisms. Ongoing treatment will continue to decrease the bioburden.

Note Regarding Target Air Quality

Air quality scale for workplaces, public buildings, schools and homes are as follows:

- Less than 100 cfu/m3 is considered clean and acceptable

- 100 to 300 cfu/m3 is marginal

- Greater than 300 cfu/m3 is not acceptable and needs corrective action