The science behind ADB

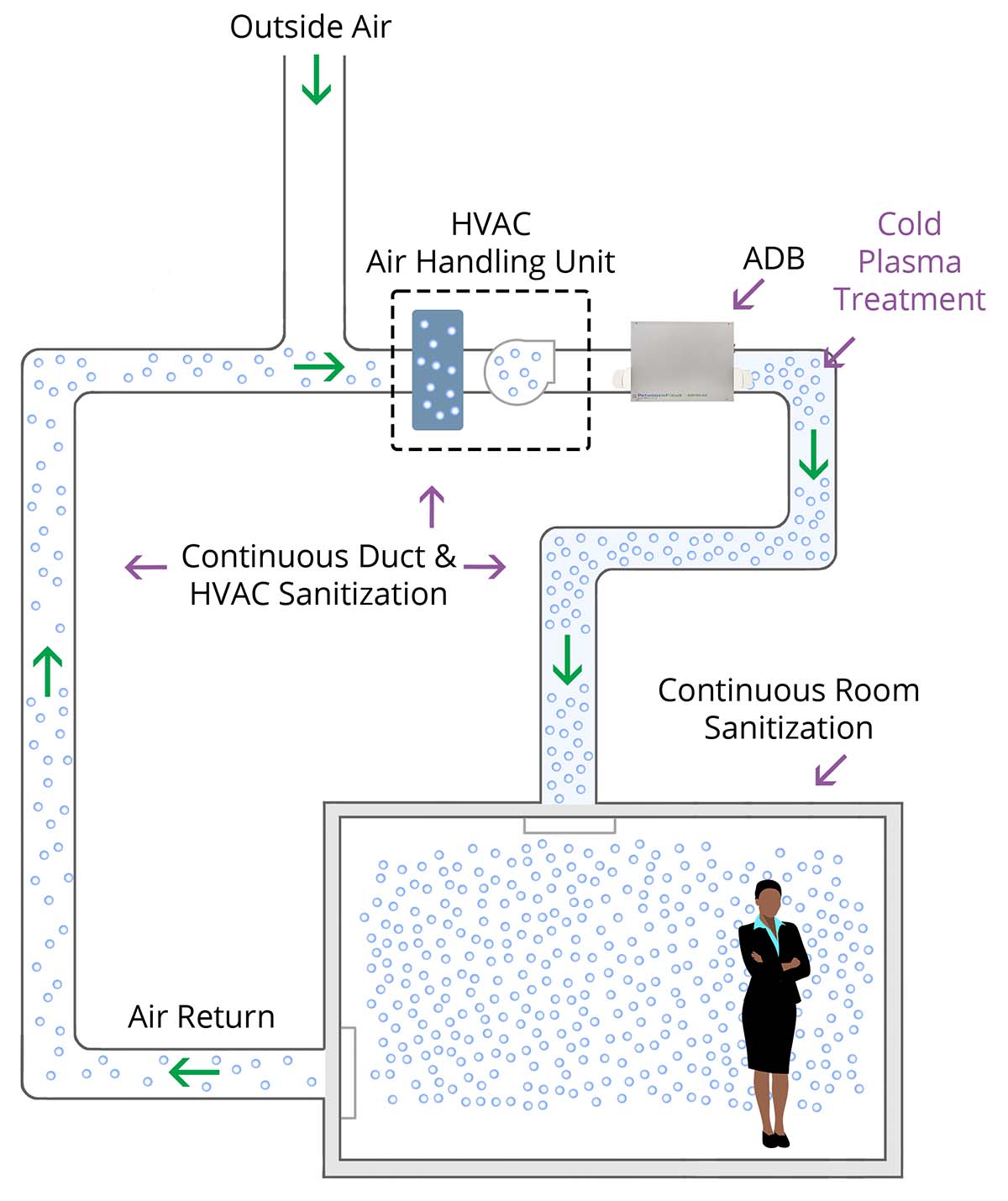

PathogenFocus' Air Disinfection Biosecurity (patent pending) technology units are highly effective against viruses (including SARS-CoV-2, the virus that causes COVID-19), bacteria, mold, spores - all common microbes including pathogens. This technology is proven safe and effective. But how does it work?

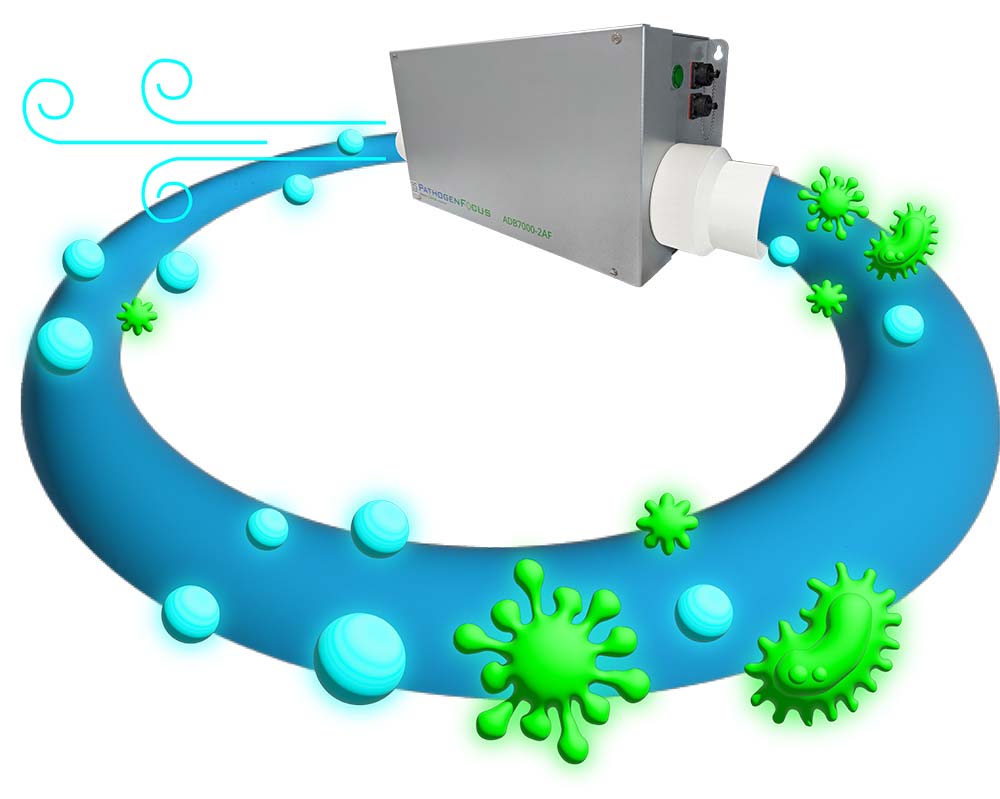

- First, ambient air and moisture are captured and exposed to high-frequency controlled electrical pulses (Modulated Dielectric Barrier Discharge) within the system's chamber and broken down at the molecular level.

- This creates a burst of highly reactive molecules with powerful biocidal properties.

- These reactive particles are then dispersed through the air via the HVAC/air handling system or standalone unit acting as airborne neutralizing agents.

- This treatment destroys microbial DNA/RNA to render them inactive.

These ADB systems utilize no consumables. They work by converting air and humidity into non-thermal plasma via Modulated Dielectric Barrier Discharge inside the unit's chamber. This process creates the treatment that is then dispersed into the space.

Our natural immune system

It's interesting to note that within our own body's immune system, when a microbe is recognized by phagocytes and engulfed, a natural immune response process called respiratory burst is initiated. Much of this process within our own body's immune response centers around this very reaction of superoxide and water to create H2O2, as well as the reaction of singlet oxygen which, as mentioned earlier, will oxidize many of a microbe's cellular components. In a way, we are essentially taking this part of our body's natural immune response to pathogens and bringing it out into our building spaces. Once the reaction is complete, we are left with water vapor and non-reactive O2.

Advantages over other potential solutions

ADB technology provides many advantages over other pathogen eradicating solutions. Utilizing ultraviolet light at 254 nanometers (UVC) is proven effective against pathogens, but relies on line of sight, so it isn't a perfect solution for hard-to-reach areas. Also, UVC can be hazardous to the skin and eyes of humans. So when UVC is utilized, it must be in either unoccupied spaces, or in indirect applications such as enclosed air boxes or upper air irradiation units. Bipolar ionization units are also being advertised as a pathogen eradicating option. However, the efficacy of these products is in question.

When comparing the various methods of pathogen eradication, another very important factor to consider is speed. Speed is critical. If an infected person enters a space and releases SARS-CoV-2 into the air, the speed in which the system inactivates the virus is of the utmost importance. ADB technology works tremendously faster than other methods in the market. The transmission of viruses such as SARS-CoV-2 is vastly diminished by the fact that airborne viruses are inactivated so quickly by ADB. Airborne SARS-CoV-2 is reduced by 90 percent in 16 seconds, and by 99.9 percent in 30 seconds using ADB.

In an independent third party testing laboratory, ADB units performed much better than other common methods of pathogen elimination. ADB achieved a 3-log reduction kill rate (99.9 percent reduction) significantly faster than the rest.