Enhanced Microbial Control with PathogenFocus

Air Disinfection* Biosecurity (ADB) seamlessly enhances mitigation of mold, bacteria, virus, and some Volatile Organic Compound (VOC) for our customers in:

- Produce, meat, poultry and dairy processing

- Hatcheries

- Food and ingredient processing

- Transportation

- Controlled environment agriculture and livestock

- Healthcare** and long-term care facilities***

- Commercial and municipal buildings

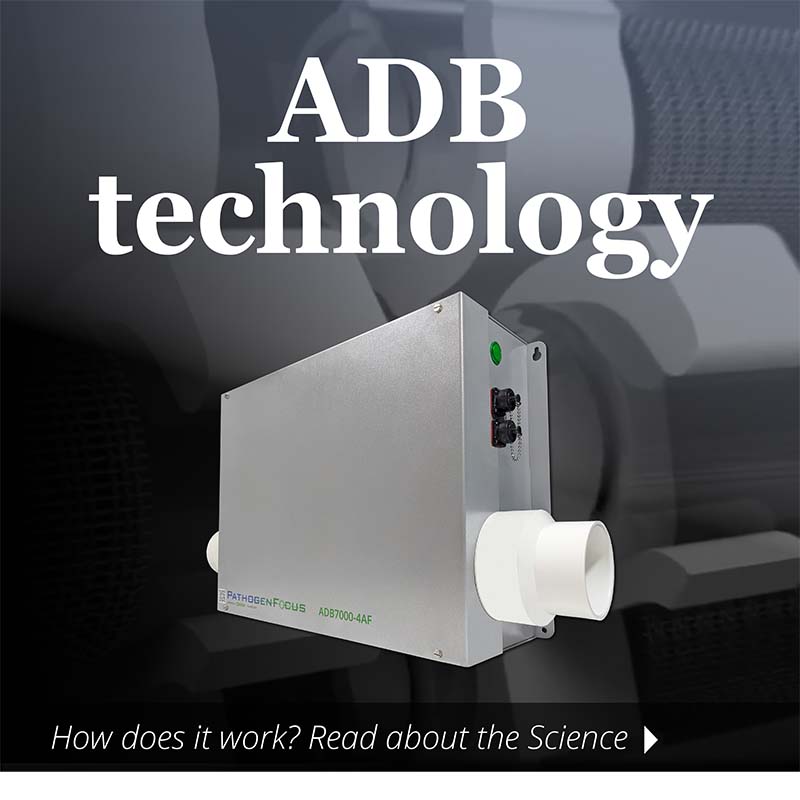

ADB is a proprietary Modulated Dielectric Barrier Discharge non-thermal (cold) plasma technology. Our systems use indoor air circulation to provide constant, fully automated, and proactive treatment of air and surfaces. ADB systems have been shown over and over to dramatically lower facilities' microbial contamination - even in the most challenging environments.

Air Disinfection* Biosecurity (ADB) seamlessly enhances mitigation of mold, bacteria, virus, and some Volatile Organic Compound (VOC) for our customers in:

- Produce, meat, poultry and dairy processing

- Hatcheries

- Food and ingredient processing

- Transportation

- Controlled environment agriculture and livestock

- Healthcare** and long-term care facilities***

- Commercial and municipal buildings

ADB is a proprietary Modulated Dielectric Barrier Discharge non-thermal (cold) plasma technology. Our systems use indoor air circulation to provide constant, fully automated, and proactive treatment of air and surfaces. ADB systems have been shown over and over to dramatically lower facilities' microbial contamination - even in the most challenging environments.

“After an extensive review of over 40 research studies, it appears that PathogenFocus ADB system's near-instantaneous inactivation of pathogens in breathing-zone air, and the corresponding significant reduction in bioburden, make this technology an innovative and important asset to any facility with stringent biosafey/biosecurity requirements.”

Mark H. Ereth, MD, Emeritus Professor, Mayo Clinic College of Medicine and Science

Advantages of ADB

Rapid and continual antimicrobial technology reduces bioburden and improves indoor air quality

Disinfection for both air AND surfaces

Engineered for use in occupied spaces

Requires no additional chemicals and leaves behind no residue

Certified to meet USDA National Organic Standards 7 CFR 205, product type "Sanitizers, disinfectants, and cleaners"

Long-term cost savings in chemical use and staff labor

Smart controller for units installed with HVAC system for ease of use

No UV components

Scalable to room/building size - flexible and adaptable

Standalone portable and wall-mounted units available

Mitigates many Volatile Organic Compounds (VOCs) including formaldehyde, toluene, and benzene

Quickly reduces ethylene, extending shelf life of produce. Certified Halal by Islamic Services of America

Meets California ozone emissions limit - CARB Certified. Complies with the requirements of the UL2998 "Zero Ozone" standard. Also meets UL867 standard (ADB 7000-AF).

Potential HVAC energy savings by reducing amount of outside air needed

Industry-leading speed, efficacy, and ease of use

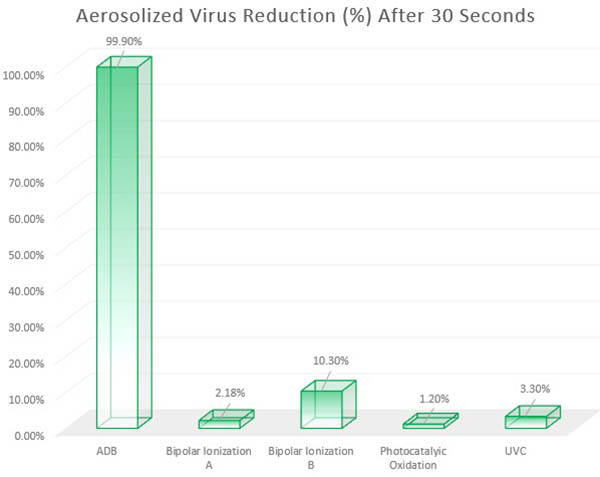

ADB: The faster, better pathogen mitigating technology

Our Air Disinfection Biosecurity units were tested in an independent third party laboratory against other popular pathogen-neutralizing products - bipolar ionization, photocatalytic oxidation, and UVC. These results are from a 2,640 cubic foot room (22 foot width x 12 foot length x 10 foot height). ADB dramatically outperformed the other products.

ADB worked significantly faster in reducing viruses and bacteria in the air and on surfaces. With the aerosolized pathogens, ADB was exponentially better - achieving upwards of 99% reduction when the other methods were only beginning to have an affect.

Performance against airborne viruses in one minute:

- PathogenFocus MDBD achieved a 7.74-log reduction (99.99998%)

- Bipolar Ionization (BPI) Brand A - 4.90909%

- Bipolar Ionization (BPI) Brand B - 23.94000%

- Photocatalytic Oxidation (PCO) - 11.54555%

- UVC - 6.96909%

ADB saw similar success against the other methods when tested against surface bacteria. PathogenFocus' MDBD units achieved a 7.89-log reduction (99.99998%) in 30 minutes. Other methods tested in that time - BPI Brand A: 71.15385%; BPI Brand B: 60.25641%; PCO: 23.07692%; and UVC: 8.333339%.

ADB: The faster, better pathogen mitigating technology

Our Air Disinfection Biosecurity units were tested in an independent third party laboratory against other popular pathogen-neutralizing products - bipolar ionization, photocatalytic oxidation, and UVC. These results are from a 2,640 cubic foot room (22 foot width x 12 foot length x 10 foot height). ADB dramatically outperformed the other products.

ADB worked significantly faster in reducing viruses and bacteria in the air and on surfaces. With the aerosolized pathogens, ADB was exponentially better - achieving upwards of 99% reduction when the other methods were only beginning to have an affect.

Performance against airborne viruses in one minute:

- PathogenFocus MDBD achieved a 7.74-log reduction (99.99998%)

- Bipolar Ionization (BPI) Brand A - 4.90909%

- Bipolar Ionization (BPI) Brand B - 23.94000%

- Photocatalytic Oxidation (PCO) - 11.54555%

- UVC - 6.96909%

ADB saw similar success against the other methods when tested against surface bacteria. PathogenFocus' MDBD units achieved a 7.89-log reduction (99.99998%) in 30 minutes. Other methods tested in that time - BPI Brand A: 71.15385%; BPI Brand B: 60.25641%; PCO: 23.07692%; and UVC: 8.333339%.

Where can ADB technology be used?

Air Disinfection Biosecurity technology works continuously and invisibly with no disruption to daily operations, neutralizing harmful pathogens and preventing potential re-contamination on air and surfaces. ADB has been utilized in the US since 2008. In that time, tens of thousands of ADB units have been utilized in over 1,000 installations.

ADB can be used in a wide variety of applications, including the below:

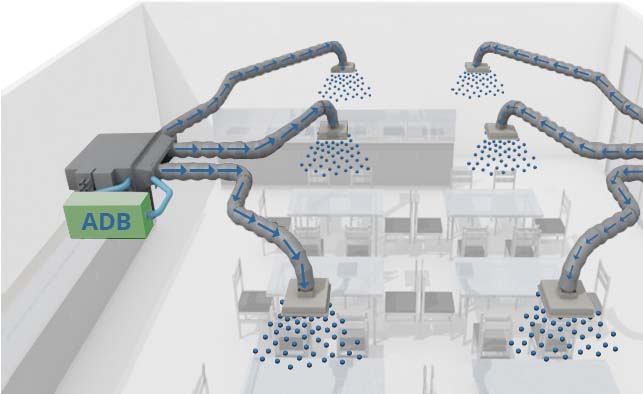

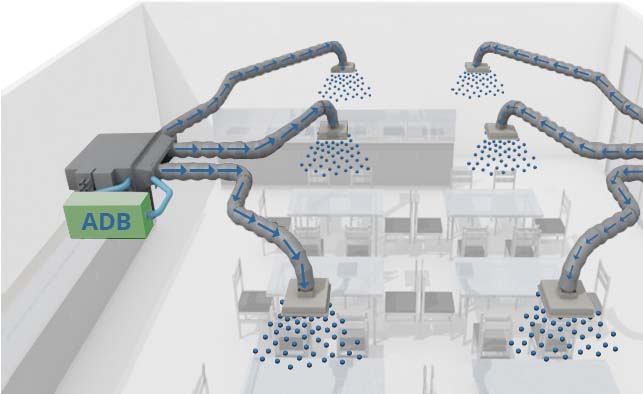

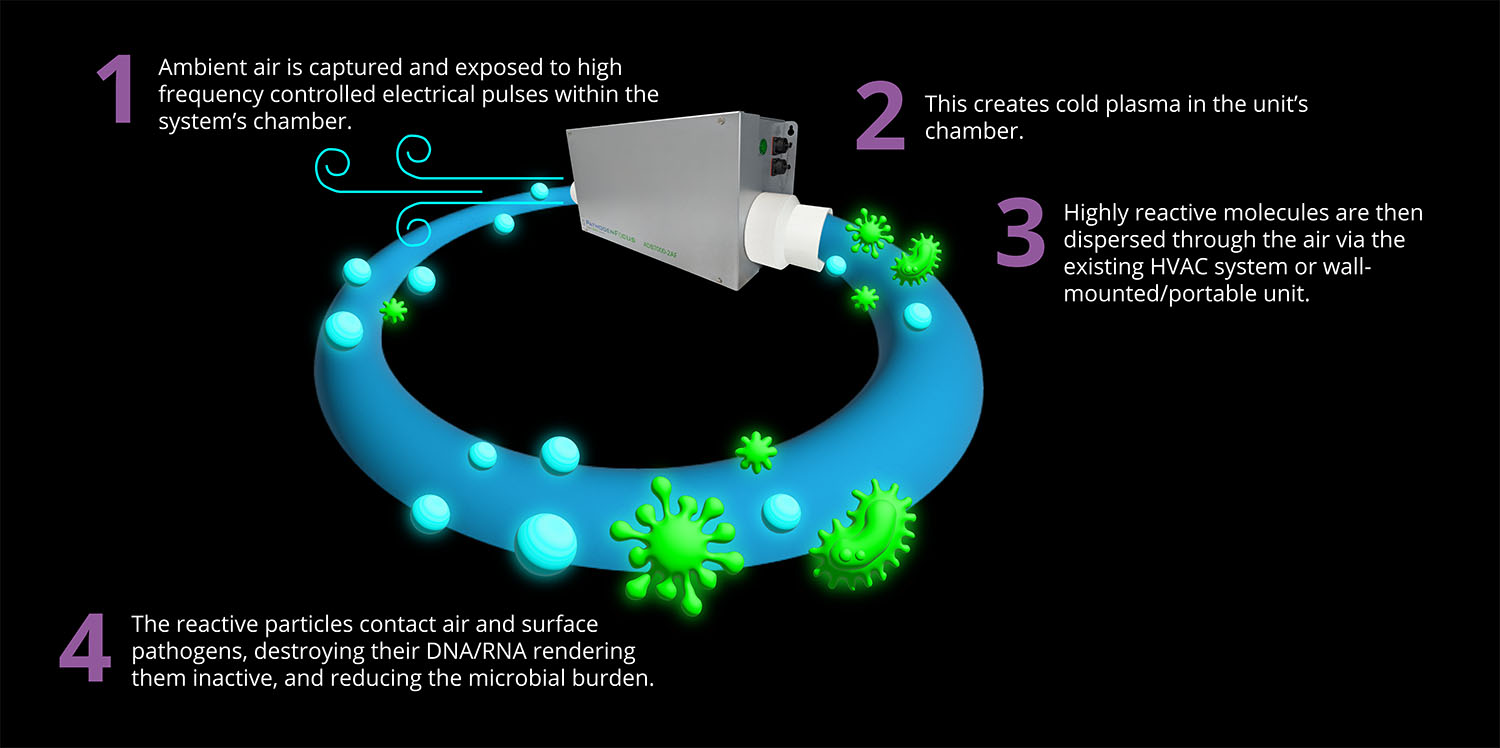

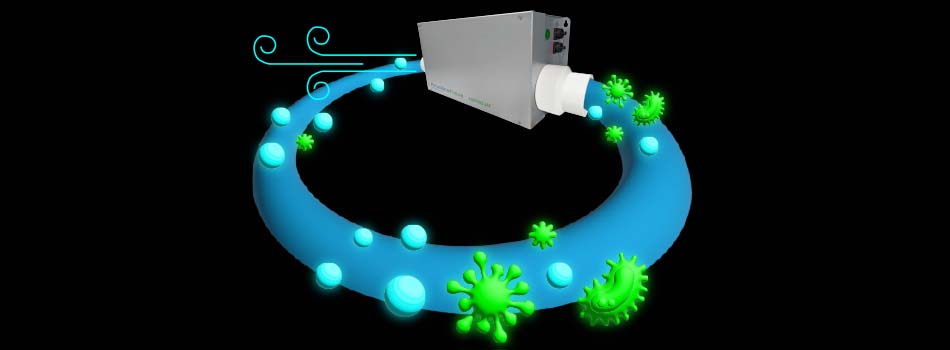

How does ADB work?

ADB proactively mitigates airborne and surface pathogens by creating cold plasma in the chamber, triggering the creation of an array of highly reactive molecules including hydrogen peroxide (H2O2), throughout the treatment space. The treatment continuously targets pathogens and other microbial contamination in air and on surfaces. ADB treatment is not limited to line-of-sight or physical distance but works everywhere air can reach. ADB is designed for use in occupied spaces, with no negative impact on workflow. These units work in conjunction with a facility's existing HVAC/air handling system, or as standalone units, and can be scaled to any size treatment space without sacrificing treatment efficacy.

1.

Ambient air is captured and exposed to high frequency controlled electrical pulses within the system’s chamber.

2.

This creates cold plasma in the unit's chamber.

3.

Highly reactive molecules are then dispersed through the air via the existing HVAC system or from the wall-mounted/portable unit.

4.

The particles contact air and surface pathogens, destroying their DNA/RNA rendering them inactive, and reducing the microbial burden.

*Disinfection claims based upon the results of 3rd-party laboratory testing of Bacteria: Acinetobacter baumannii, Bacteroides fragilis, Burkholderia cepacia, Clostridium sordellii, Carbapenem-resistant Enterobacteriaceae, Enterococcus faecalis, Escherichia coli O157:H7, Klebsiella pneumoniae, Morganella morganii, Mycobacterium abscessus, Staphylococcus aureus, Methicillin-resistant Staphylococcus aureus, Vancomyin-resistant Staphylococcus aureus, Clostridioides difficile - Spores, Clostridioides difficile - Vegetative, Pseudomonas aeruginosa, Salmonella enteritidis, Geobacillus stearothermophilus, Serratia marcescens, Lactococcus lactis. Viruses: MS2 bacteriophage, Human Coronavirus 229E, Monkeypox Virus NR-2500 & VR-677, Influenza A (H1N1), Hepatitis A, B, & C, Norovirus, Rhinovirus. Fungi: Candida auris. Methodologies: (AOAC) Association of Official Analytical Chemists, (BAM) Bacteriological Analytical Manual methods, and (RSM) Response Surface Methodology. (norovirus/mrsa/H1N1). Chamber size 2,640 ft3. Samples in triplicate.

**PathogenFocus does not make health claims.

***The PathogenFocus MDBD cold plasma air treatment system is not intended for use on medical devices.