Benefits to food processing and horticulture

Spoiled food: Expensive and wasteful

Every year, American grocery stores waste 16 billion pounds of food, according to rts.com. Meat and produce spoilage from these stores requires much of the food to be discarded before it even reaches a household.

All this waste comes at an extreme cost. According to a RELEX Solutions and Elastic Solutions survey, average food spoilage equates to around $70 million per year. One-third of the respondents from this survey said the cost of expired or spoiled products totaled 1.0 to 1.4 percent of their business' total revenue.

According to refed.com, American consumers, business and farms spend $218 billion processing and handling food that is never eaten.

Air Disinfection Biosecurity (patent pending) technology can and has been used in many facets of the food processing industry. ADB neutralizes harmful disease-causing pathogens - bacteria, mold, mildew and viruses. It reduces ethylene and helps mitigate unpleasant odors. ADB can assist in processing areas, cooling areas like freezers or refrigerators, as well as the actual transport of the product. ADB can also be used in grocery stores and restaurants.

PathogenFocus products are certified Halal by Islamic Services of America.

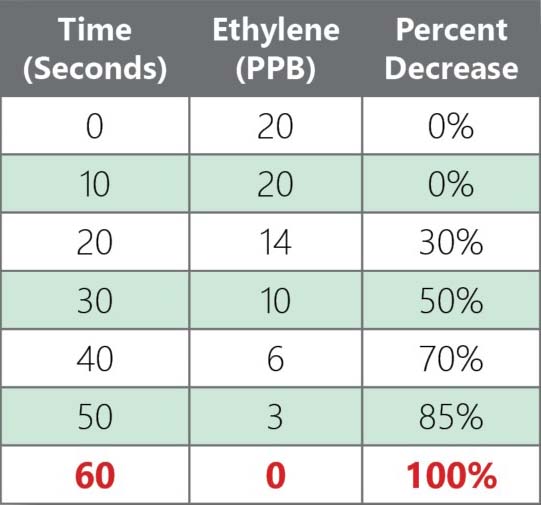

Reduce spoilage by quickly neutralizing ethylene

Ethylene is a primary source of spoilage in fruits and vegetables. Ethylene is an unsaturated carbon gas that stimulates fruit ripening. It shortens the life of many fruits and veggies in grocery stores by quickening the ripening process.

ADB systems can reduce spoilage and increase shelf life by dramatically reducing ethylene.

In an independent third-party laboratory test, 20 parts-per-billion (ppb) of ethylene was treated by ADB. In about one minute, the ethylene was untraceable. A 5 ppb measure of ethylene was eliminated in about 30 seconds.

Combat contamination in meat processing

Bacterial contamination is a huge concern in all phases of the meat processing industry, and is a leading cause of food recalls. Salmonella, norovirus, Clostridium perfringens, Campylobacter, E. coli, Listeria and Cronobacter are all dangerous pathogens than can cause food poisoning or even death. All of these pathogens can be mitigated with ADB technology.

ADB technology can be used in many meat processing applications - from the processing phase, to storage, transportation, and retail settings - to mitigate these concerns. ADB has been shown to reduce pathogen contamination in meat, extend shelf life, control cross-contamination, and reduces losses. ADB technology provides continuous mitigation of bacteria, mold, mildew and viruses which lead to these food-borne illnesses and negatively affect the product's condition. It accomplishes this without the need for chemical consumables, and without leaving behind any residue.

Before ADB: Food storage area with many contaminants - mold spores (powdery mildew), fungi, yeast, bacteria, viruses, odors, ethylene.

With ADB treatment: ADB transforms the air into a sanitizing vehicle, reducing ethylene and protecting the product's integrity without changing its organoleptic characteristics.

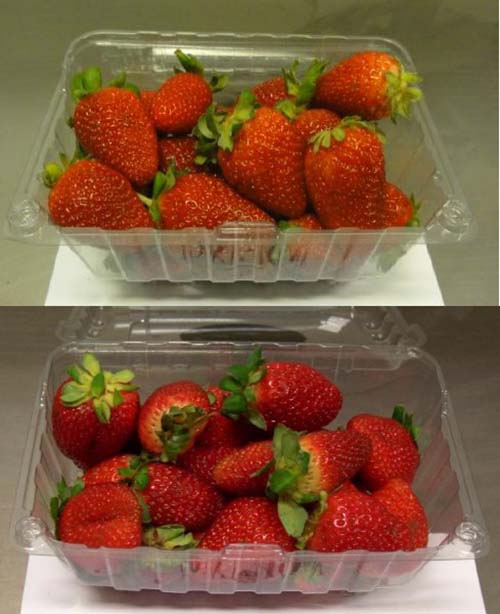

Protect your produce and extend shelf life

Tomatoes: Control room.

Tomatoes: With ADB treatment.

Strawberries: Control room.

Strawberries: With ADB treatment.

Kiwis: Control room.

Kiwis: With ADB treatment.

Added safety for customers and staff

Since ADB is completely safe for occupied spaces, it provides protection for retail staff and customers when its needed the most. ADB quickly, safely, and effectively neutralizes airborne and surface pathogens. ADB has been tested against many known pathogens and has proven to be extremely effective - including SARS-CoV-2 surrogate, the virus that causes COVID-19.

Click here to learn more about ADB's pathogen neutralizing capabilities.